- Unternehmen

- Produkte

- Karriere

- Umwelt

- News

- Downloads

- Kontakt

Qualität in Edelstahl

Höchste Qualität der Produkte war und ist zu allen Zeiten oberstes Gebot im Hause Lohmann.

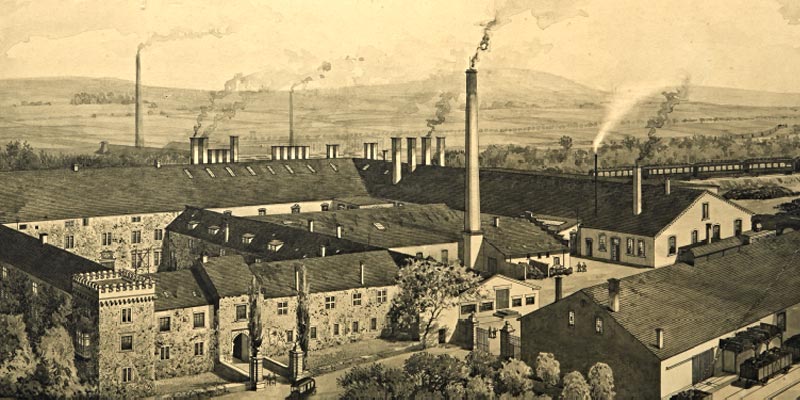

Familienunternehmen seit 1790

Unser Firmengründer Johann Friedrich Lohmann hat vor über 225 Jahren eine Tiegelgussstahlfabrik im Haus Witten gegründet. Damit setzte er den Grundstein für die außergewöhnliche Geschichte des Unternehmens.

Produkte

Wir produzieren in leistungsstarken Verfahren Blech- und Stabstahlprodukte aus Schnellarbeits-, Werkzeug- und Spezialstahl, hitzebeständigen und verschleißfesten Edelstahlformguss sowie Schweißverbundkonstruktionen.

Denken in Generationen

Das Familienunternehmen wird heute in der siebten Generation mit großem Engagement geführt.

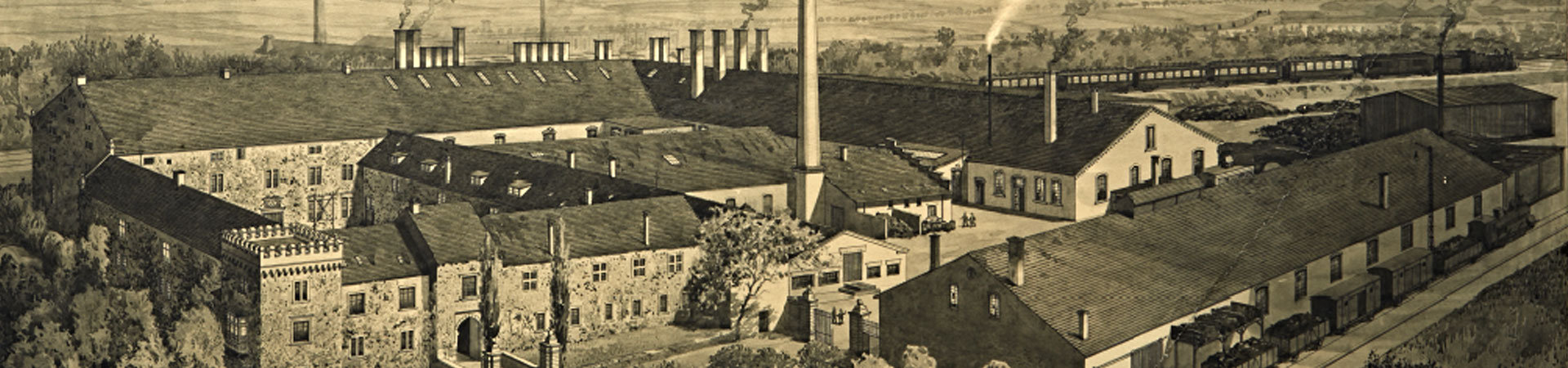

Made in Witten

Die Familie Lohmann war für Witten von nachhaltiger Prägung.

Für eine Saubere Umwelt

Die Pflege eines sensiblen Umweltbewusstseins gehört zum moralischen Selbstverständnis der Friedr. Lohmann GmbH.

Talente schmieden

Wir sind ständig auf der Suche nach engagierten Mitarbeitern und Auszubildenden.