- Company

- Products

- Careers

- Environment

- News

- Downloads

- Contact

Annen Plant

At our stainless steel foundry in Witten-Annen, we manufacture highly wear-resistant and heat-resistant cast parts.

You tell us what you need and we´ll produce it!

Our dedicated sales team is committed to the principle that the customer is king.

We pride ourselves on :

Just contact us for a non-binding offer. We would be happy to discuss your requirements in person!

Contact: Friedr. Lohmann GmbH

Brauckstrasse 37

58454 Witten-Annen

Telephone +49 (0) 2302 8906-45

Fax +49 (0) 2302 8906-30

guss.info@lohmann-stahl.de

Our production planning staff, in close coordination with our customers and our technical office (engineering) as well as with the pattern making department, develop the production design of components and assemblies.

The production, assembly, and testing process steps are specified according to the technical requirements. Our production planning staff specifies which process steps we will execute and which will be executed by partner suppliers in order to provide the most economical solution possible. In all cases, we look after the management of the entire project and assume responsibility for the efficient implementation of the project.

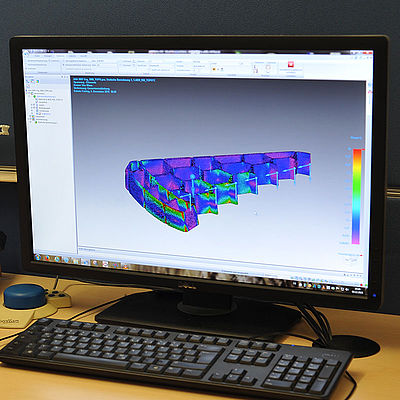

Our Engineering department is particularly highly regarded by our customers. We are able to develop a custom charging concept based solely on the component to be hardened. Using the know-how gained from over 225 years of experience in stainless steel production and with the aid of modern technologies such as 3D CAD, solidification and mold filling simulations, topology optimization, FEM simulations, 3D printing, material simulation, and rapid prototyping, we are able to realize tailor-made solutions. We would be happy to make your challenges our challenges…

The newly established pattern store allows efficient and optimized access to our stock of metal casting patterns. This means shorter delivery times for our customers.

As we have a large stock of patterns, it is often possible to use existing patterns and thus reduce pattern costs for our clients.

Friedr. Lohmann GmbH´s high performance core shop has a range of core shooting machines that use a variety of different methods. They operate according to the resole-CO2 method and Croning method with a shooting volume of 2.5 to 20.0 liters. In addition to the core shooting machines, we also have a manual core shooter available on which we can produce large and special cores using the resole-CO2 method and croning method.

Based on the batch sizes and individual requirements of the area of application, the cast parts are manufactured in our own manual molding facility or using molding machines, automatic molding facility, and shell-molding facility. The weight per piece ranges from 0.5 to 1800 kg. Our automatic molding facility is a milestone represents a milestone in our long-term investment policy and makes us an even better stainless steel casting partner for our clients thanks to the corresponding increases in quality and performance.

Our high-quality steels are melted in our induction melting furnaces. The relatively small furnaces allow us greater flexibility to react to our customers' wishes. We can basically melt almost any high-alloyed steels as well as nickel and cobalt-based alloys. We can also take on commissioned melting and block casting jobs.

Our modern cleaning shop is located in a spacious building. New handling, lifting and extraction equipment and extraction systems at every workstation as well as an enclosed separating machine ensure quality, safety and an excellent working environment.

We use mechanical machining methods such as turning, milling, and drilling as well as welding to process our stainless steel products for a variety of requirements and purposes. Together with our manufacturing partners, we have modern CNC, universal turning machines, and milling machines at our disposal.

The assembly of components such as charging systems as well as chain link conveyor belts, for example, rounds off our range of manufacturing capabilities.

Our customers appreciate "Lohmann quality"! This high quality standard is ensured by our quality management system. We have all the equipment we need for this purpose available, for example:

Our shipping department is responsible for ensuring the smooth delivery of your products. A particular highlight is the wide range of replacement parts available for wheel blasting machines. Our warehouse contains a stock of almost every common component for a variety of different types of systems and manufacturers. This enables us to get your replacement parts shipped out within one working day.

Success is impossible without motivated employees! We are particularly proud of our team and work hard to ensure that our employees identify with the company. It is only possible to survive in the market when you have reliable, motivated, and innovative employees. Our very long company history, "Quality is our passion since 1790", proves this point.

Friedr. Lohmann GmbH

Werk für Spezial- & Edelstähle

Ruhrtal 2

58456 Witten-Herbede

Phone: +49 (0) 2302 - 7014-0

Fax: +49 (0) 2302 - 7014-189

Postfach 32 62

D-58423 Witten

Friedr. Lohmann GmbH

Edelstahlgießerei

Brauckstr. 37

D-58454 Witten-Annen

Phone: +49 (0) 2302 - 8906-0

Fax: +49 (0) 2302 - 8906-30

General enquiries for steel products

(bar and sheet steel):

Henning Bäing

Phone: +49 (0) 2302 - 7014-156

E-Mail: stahl.info@Lohmann-Stahl.de

General enquiries for foundry products (wear and heat-resistant castings):

Karsten Reuter

Phone: +49 (0) 2302 - 8906-45

E-Mail: guss.info@Lohmann-Stahl.de