- Company

- Products

- Careers

- Environment

- News

- Downloads

- Contact

climate footprint / climate neutrality

The first CO2-neutral foundry

THE FIRST CO2-NEUTRAL FOUNDRY

The deadline for industry has been set: The industry must achieve climate-neutral production no later than 2045. With our stainless steel foundry in Witten-Annen, we are already climate-neutral today thanks to our own hydroelectric power plant, our commitment to sustainability, and our compensation for unavoidable CO2 emissions, and are therefore a pioneer in the industry.

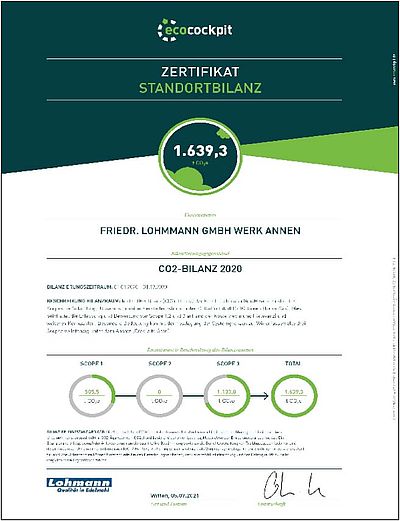

The foundry of the Friedr. Lohmann GmbH has been climate-neutral in Scope 1 and 2 since January 2020. Since mid-2021, the upstream and downstream processes in Scope 3 have also been taken into account. All production processes are to be decarbonized to the greatest extent possible. Only the remaining emissions need to be compensated, which means our foundry in Witten-Annen has been 100% climate-neutral since mid-2021.

The GHG balance (CO2 balance) of the Friedr. Lohmann GmbH takes all three GHG Protocol scopes into account. We prepare our carbon footprint statement according to the GHG Protocol (Greenhouse Gas Protocol). This includes the documentation and evaluation of Scope 1, 2, and 3 based on a calculation of costs (relevance) and other key figures.

Particular attention is paid to the definitions of the system boundaries. We completely document all three scopes according to the “cradle to gate” approach (completeness). This applies in particular to Scope 3, which we evaluate in great detail. We check our evaluations regularly to achieve continuous improvements in the quality of the data and in the calculation factors (consistency, accuracy). We do this because this is the only way to obtain an accurate analysis.

Scope 1 includes direct emissions, for example emissions arising from the use of fossil energy sources. At Lohmann, these emissions arise primarily through the use of natural gas and gasoline or diesel in company vehicles. In addition, there are emissions arising from small quantities of process gases.

Scope 2 includes purchased or acquired energy. At Lohmann, this only applies to electricity, which we generate for our foundry in a climate-neutral manner using our own hydroelectric power plant and our own photovoltaic system. For this reason, there are no Scope 2 emissions at Lohmann. The footprint for the construction of the plants is taken into account in Scope 3.

Scope 3 includes a large number of emissions from upstream and downstream processes. The upstream processes are especially important and were taken into account accordingly. The goods and services purchased were fully documented and evaluated. Capital goods such as investments were valued and depreciated according to the imputed depreciation with the corresponding CO2 footprint. Fuels and purchased or acquired energy, insofar as these do not fall under Scope 1, have also been taken into account. Employee commuting to the workplace was documented down to the kilometer and evaluated. Upstream transportation, for example of raw materials and supplies, was also documented and evaluated wherever such transport was the responsibility of Lohmann. The waste produced was also documented and evaluated. Furthermore, business travel by air or car, including business travel by our independent sales representatives, was documented and evaluated. Rental and leasing rates were also documented and evaluated. In the downstream processes included in Scope 3, all items required for the transport and distribution of our products to our customers’ factory gates, whenever the transport was initiated by Lohmann, were documented.

COMPENSATION FOR UNAVOIDABLE EMISSIONS

Compensating for unavoidable emissions should only be the last step taken after all other efforts have not achieved or have not yet achieved the goal set.

Lohmann has already been able to reduce emissions significantly in recent years, but unfortunately we, and especially our environment, have not yet reached the point where we can produce completely free of emissions.

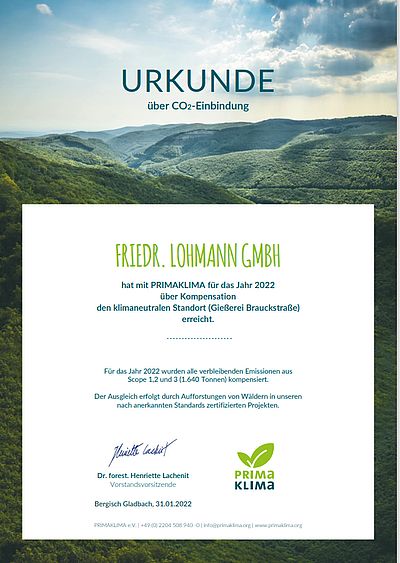

For this reason, compensation unfortunately still plays far too great a role. If compensation is used, it is also important to ensure that it is implemented effectively and reliably.

We only work with certified partners for this reason. We ensure as best we can that our compensation also makes an effective contribution to capturing CO2. The estimation of the CO2 absorption capacity of a tree is only a rough average value in any case. As a general rule of thumb, one can say that a tree in Germany absorbs an average of 10 kg of CO2 per year.

For projects near the equator, this value is higher because the trees can grow all year due to a year-round growing season, which means their growth is not slowed down in winter as is the case here in Germany. We currently work together with our partner "Prima Klima e.V." to compensate for our unavoidable emissions in 2020, 2021 and 2022.

Together we support a project in Uganda in which a degraded rainforest in the Kibale National Park is undergoing reforestation. (https://www.primaklima.org/ueber-uns/unsere-projekte/projekt/uganda-224/

It is important for us that our commitment is sustainable, traceable, and feasible. Achieving additional positive effects through the involvement of the local population is also very important to us. For the local people, the Kibale National Park project offers various training and job opportunities in the forestry sector.

Since mid-2021, we have compensated all unavoidable Scope 1, 2 and 3 emissions.

Climate and environmental protection have always played an important role at our company.