- Company

- Products

- Careers

- Environment

- News

- Downloads

- Contact

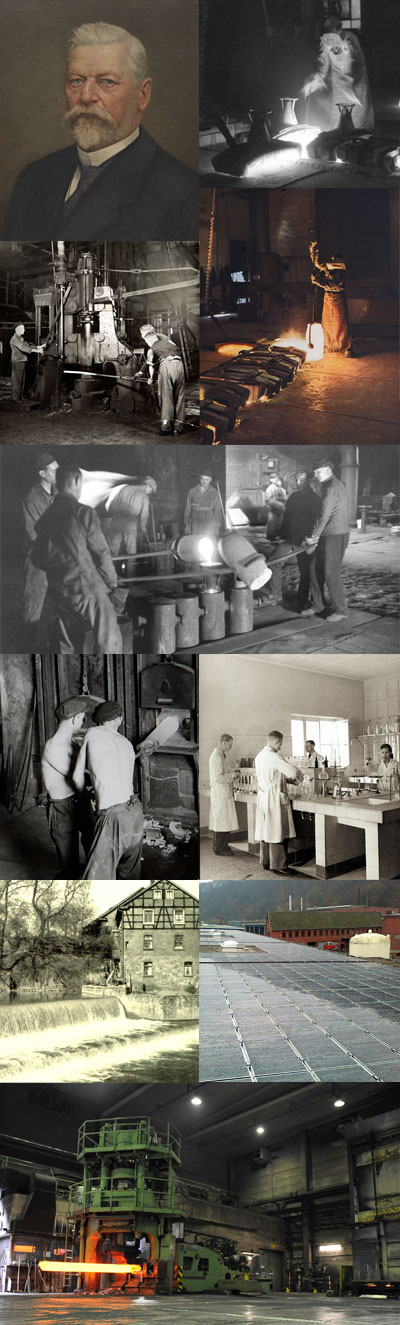

Thinking in generations

The seventh generation of the Lohmann family today runs the business with the same commitment as previous generations. Even today - after over 225 years - LOHMANN is still owned by the family.

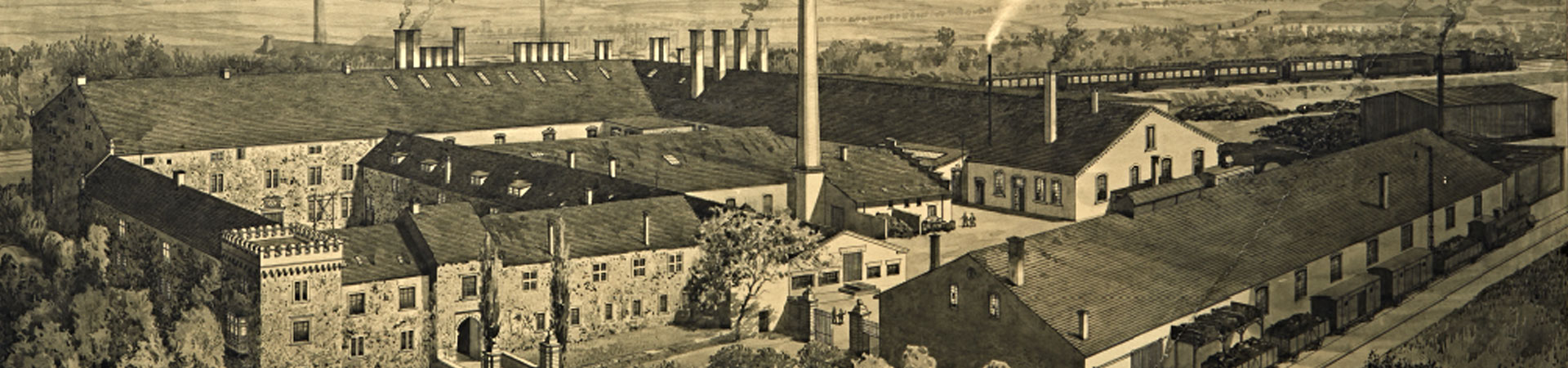

Quality since 1790

The two traditional locations of LOHMANN, still part of our business today, in the districts of Herbede and Annen, emerged from the "steel factory" founded in 1790 in Witten by Johann Friedrich Lohmann.

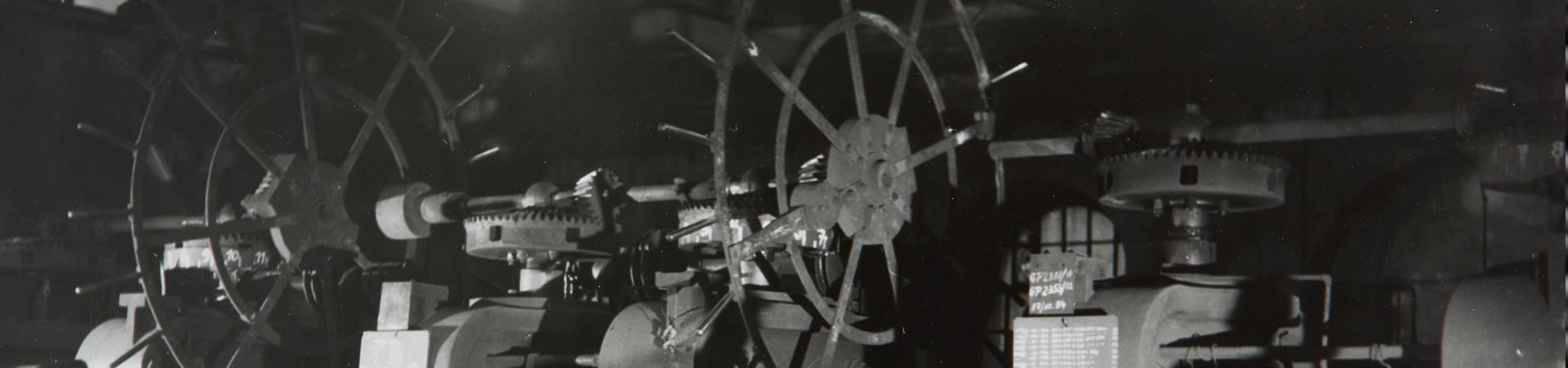

Family and company archive

The family and company archive in Witten-Herbede demonstrates that history is a vibrant part of our corporate culture.