- Company

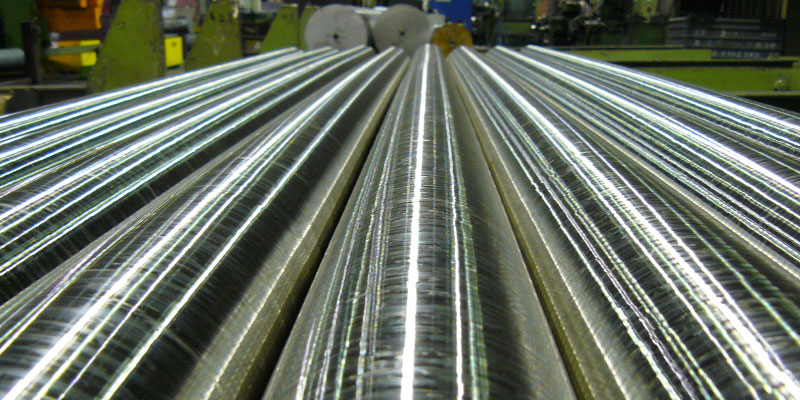

- Products

- Careers

- Environment

- News

- Downloads

- Contact

High-speed steels

High-speed steel is characterized by high wear resistance, high processing hardness, adequate toughness, high resistance to tempering, and high red hardness.

Cold-work steels

The strengths of cold-work steel are its high degree of hardness, high wear resistance, good toughness, and good dimensional stability while still remaining adequately workable.

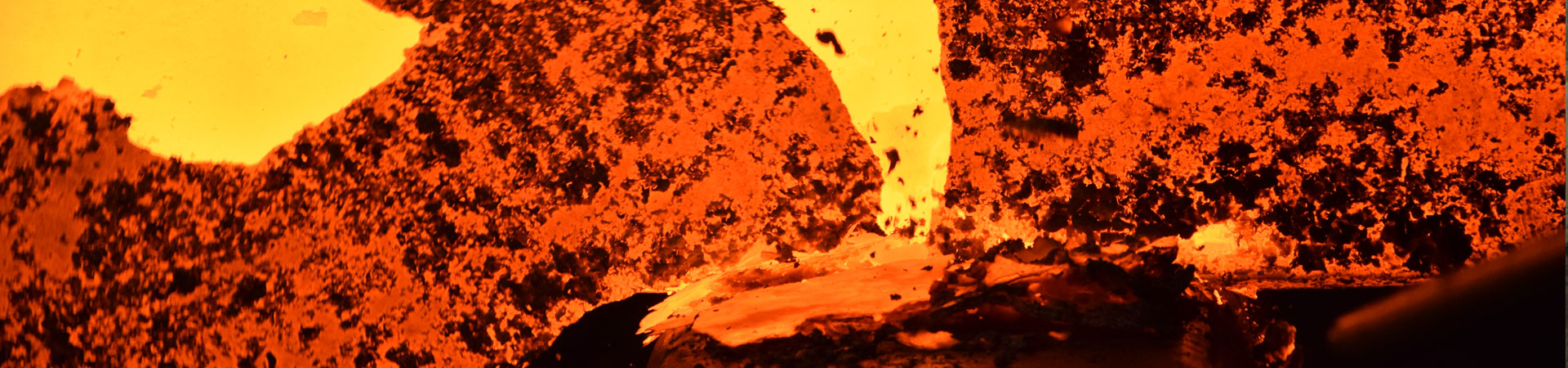

Hot-work steels

Hot-work steels are characterized in particular by its high toughness and strength at high temperatures, good thermal fatigue resistance, and high wear resistance at high temperature.

Corrosion-resistant steels

Corrosion-resistant steels are characterized by increased resistance to acids and corrosion.

Powder-metallurgical tool steels

Powder-metallurgical steels are characterized by high toughness, the highest possible wear resistance, high processing hardness, and long tool lives.

Special materials

Regardless of whether you're looking for standard or custom-made special materials, we can offer you the right material for every application.