- Company

- Products

- Careers

- Environment

- News

- Downloads

- Contact

Services and commissioned processing

Through the use of all the production facilities at our two locations, we are able to offer various processing services on a commission basis.

Contract melting is carried out in the induction furnace. One advantage is the batch size of approx. 6.5 tons. This allows us to react flexibly to our customer's wishes and produce smaller quantities economically. To further process the melt, we have a vacuum degassing plant (VD/VOD) as well as an ESR plant. We have molds in the widest possible range of sizes and shapes available. You will find more detailed information in our mold format list. If you have special requirements, we can expand our inventory of molds at any time. Our ingots can be delivered hot if required. We can also deliver annealed ingots from our heat treatment furnaces.

On our rolling mill, we are able to roll a wide variety of semi-finished goods on a contract basis. Thicknesses from 1.0 mm to 22 mm are included in the standard program, depending on the semi-finished goods delivered to us. For such jobs, exact coordination is necessary prior to melting to ensure an optimal result meeting the customer's requirements.

We have fully automatic band saws with a maximum width or diagonal of 530 mm. The maximum bar weight must not exceed 4.5 tons.

Rolled and forged barproducts in flat sizes and up to 200 square / 230 dia can be straightened on two ram straightening lines. The max. straightening bar length is approx. 4,000 mm.

Forging work on our forging hammers and our press with subsequent annealing.

Annealing up to 1250°C. Quenching in water, deposition in the air and specific cooling in the furnace are possible. The maximum unit weight is 3,500 kg. At an annealing temperature of up to 1250° C we are able to treat bar lengths of up to 5,300 mm, at a temperature of up to 1050°C the bar length can be up to 6,000 mm.

Possible to peel from Ø 40 mm to approx. Ø 120 mm.

We have fully automatic band saws with a maximum width or diagonal of 530 mm. The maximum bar weight must not exceed 4.5 tons.

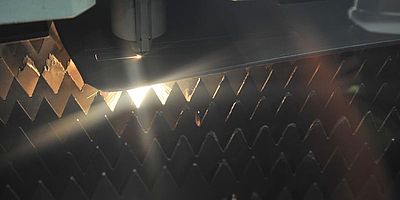

Laser blanks

Laser-cut blanks according to a drawing or a .dxf file / tolerances depending on the contour and after coordination

We have an efficient overhead conveyor blasting machine at our disposal. We use steel grain. We can blast sheets from a minimum of 1000 x 500 mm up to a maximum of 3000 x 1000 mm. The maximum piece weight is 250 kg. For unit weights of up to 100 kg, we have a very economical automatic feeding system for the system.

High-alloyed scrap

Steel scrap recycling makes a significant contribution to resource efficiency and sustainability. Due to the fact that steel scrap can be recycled any number of times without a loss of quality, recycling steel improves the life cycle assessment of stainless steel.

Even the highest quality charging materials such as baskets, grates, or even furnace rollers, for example, reach the "end of their lifetimes" eventually. This also applies to forging dies made of tool steel that are used in forming technology or in machine blades and circular saws, for example. However, even these now unusable materials are still worth a lot of money. We would be pleased to send you an offer to purchase your scrap at current market prices.

However, even these now unusable materials are still worth a lot of money. We would be pleased to send you an offer to purchase your scrap at current market prices.

We weigh and analyze your scrap at our company and create an exact list of the quality and quantity of your scrap. Our work starts after that. We crush and sort the scrap properly and feed this important raw material back into our production process. By reprocessing this scrap, both we and you make an important contribution to the protection of the environment through careful use of the raw materials.

Contact for tool steel:

Mrs. Birgit Hage

Telephone: 0049 (0) 2302 7014-150

Email: hage@lohmann-stahl.de

Contact for charging materials:

Mr. Karsten Reuter

Telephone: 0049 (0) 2302 8906-46

Email: reuter@lohmann-stahl.de