- Company

- Products

- Careers

- Environment

- News

- Downloads

- Contact

Heat-resistant castings

We manufacture grates and charging supports based on a modular design as well as chain link conveyor belts...

Base trays form the "basis" of almost every type of furnace. They are used directly as charge carriers or in connection with fixture structures and as charging fixtures made of high-alloyed steel cast. Lohmann manufactures base trays in a wide variety of different sizes and has numerous models available.

The product range extends from individual parts with sizes of up to 1400 x 1600 x 130 mm to mass production series containing several 1000 parts.

Our products (hardening equipment, hardening accessories) are used in particular in chamber furnaces, pusher-type furnaces, vacuum furnaces, industrial furnaces, conveyor furnaces, and shaft furnaces.

Stackable trays that are customized to meet the requirements profile are used in the mass production of transmission parts in particular. As a supplier for hardening shops with their own design departments, Lohmann offers its customers support as early as the planning phase. Our customers appreciate our consulting and engineering services for these charging components made of heat-resistant cast steel.

We would be pleased to "develop" tailor-made solutions for your process as well.

Charging systems, being the link between the workpieces to be treated and the furnace, straightening machine, or everything in between, play an especially important role. We manufacture base grids, top grids, and charging supports made of heat-resistant steel in standard dimensions based on a modular design or according to the customer's individual requirements. Through intensive dialogs between users and foundries, it is possible to develop the most economical solution by optimally adapting the charging fixtures to the (usually) fully automatic production process.

Our cast baskets are characterized in particular by their extreme durability. We offer a wide range of standard baskets. Custom baskets are also possible, in which case they are individually adapted to the customer requirements. Our baskets are finished using the mesh of your choice. We can also overhaul or repair your baskets at our facilities, of course.

To be able to fulfill the large number of different requests from our customers, Lohmann maintains a comprehensively stocked warehouse of meshes in different qualities and mesh sizes. We can also deliver pressure welded gratings, perforated sheets, and expanded metal.

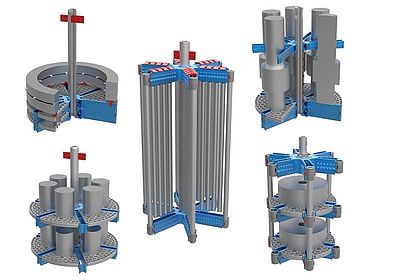

Pit furnace fixtures are a particular strength of Lohmann. We are able to offer our standardized, third generation shaft furnace fixtures in diameters from 650 to 2000 mm without modeling costs. These fixtures are characterized especially by their low empty weight in combination with a high loading capacity as well as enormous flexibility. We naturally will provide all necessary load curves as well as the corresponding CE Declaration of Conformity. Crack testing as well as functional testing and, if necessary, servicing are also part of the Lohmann portfolio of services offered.

Cast link belts and furnace conveyor belts for the high and low temperature range can be delivered as finished components for continuous furnaces. The individual links are formed according to the customer's requirements with breakouts, overlaps, bars, cams, or curves according to the process technology and quality of the heat treatment process. Our offer is rounded off by ready-to-install drive and deflection rollers as well as conveyor rollers.

If desired, we can also give your cast link belt a general overhaul in our facilities.

We manufacture a number of different furnace rollers in a wide variety of diameters and lengths. From a single part to mass-produced parts and a wide range of materials, almost every design of furnace roll is possible.

Lohmann offers furnace accessories such as slotting heads, support beams, lifting beams, fan impellers, chain guides, rollers, and radiant heating tubes for a whole range of different furnace types.

A number of anchors, brackets, and threaded studs are needed to produce refractory linings in industrial furnaces. Lohmann also offers a wide range of products made of various materials for this area, too.

| Norm Werkstoff‑Nr. Standard Material No. | Lohmann Werkstoff‑Nr. Lohmann Material No. | Werkstoff Bezeichnung Material Designation | Hauptlegierungselemente in Masse‑% Richtanalyse Main alloy elements in mass % Componential analysis | höchste Anwendungstemperatur in Luft in °C highest application temperature in the air in °C | Versprödungsbereich °C Embrittlement range °C | Beständigkeit gegenüber Gasen Resistance to gases | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Cr | Ni | Sonstige Other | 400–500 | 600–900 | schwefelig (reduzierend) a) | stickstoffhaltig sauerstoffarm b) | carburazione c) | ||||

| 1.4710 | 1.4710 | GX30CrSi7 | 0,3 | 1,8 | 7 | 750 | 0 | 0 | +++ | + | + | ||

| 1.4729 | 1.4729 | GX40CrSi13 | 0,4 | 1,8 | 13 | 850 | 0 | 0 | +++ | + | + | ||

| 1.4740 | 1.4740 | GX40CrSi17 | 0,4 | 1,8 | 17 | 900 | + | + | +++ | + | ++ | ||

| 1.4743 | 1.4743 | GX160CrSi18 | 1,6 | 1,8 | 18 | 900 | + | ++ | +++ | + | ++ | ||

| 1.4745 | 1.4745 | GX40CrSi24 | 0,4 | 1,4 | 24 | 1050 | + | ++ | +++ | + | ++ | ||

| 1.4776 | 1.4776 | GX40CrSi28 | 0,4 | 1,8 | 28 | 1150 | + | ++ | +++ | + | ++ | ||

| 1.4777 | 1.4777 | GX130CrSi29 | 1,3 | 1,8 | 29 | 1100 | + | ++ | +++ | + | ++ | ||

| 1.4823 | 1.4823 | GX40CrNiSi27-4 | 0,4 | 1,8 | 27 | 4 | 1100 | + | ++ | ++ | ++ | ++ | |

| 1.4825 | 1.4825 | GX25CrNiSi18-9 | 0,25 | 2,0 | 18 | 9 | 900 | 0 | 0 | + | ++ | ++ | |

| 1.4826 | 1.4826 | GX40CrNiSi22-10 | 0,4 | 2,0 | 22 | 10 | 950 | 0 | + | + | +++ | ++ | |

| 1.4832 | 1.4832 | GX25CrNiSi20-14 | 0,25 | 2,0 | 20 | 14 | 950 | 0 | 0 | + | ++ | ++ | |

| 1.4837 | 1.4837 | GX40CrNiSi25-12 | 0,4 | 2,0 | 25 | 12 | 1050 | 0 | + | + | ++ | ++ | |

| 1.4840 | 1.4840 | GX15CrNi25-20 | 0,15 | 1,3 | 25 | 20 | 1100 | 0 | + | + | +++ | ++ | |

| 1.4848 | 1.4848 | GX40CrNiSi25-20 | 0,4 | 2,0 | 25 | 20 | 1100 | 0 | + | - | +++ | ++ | |

| 1.4805 | 1.4805 | GX35NiCrSi25-21 | 0,35 | 1,8 | 21 | 25 | 1000 | 0 | 0 | + | +++ | ++ | |

| 1.4806 | 1.4806 | GX40NiCrSi35-17 | 0,4 | 2,0 | 17 | 35 | 1000 | 0 | 0 | - | +++ | +++ | |

| 1.4807 | 1.4807 | GX40NiCrSiNb35-18 | 0,4 | 2,0 | 18 | 35 | Nb | 1000 | 0 | 0 | - | +++ | +++ |

| 1.4849 | 1.4849 | GX40NiCrSiNb38-19 | 0,4 | 2,0 | 19 | 38 | Nb | 1020 | 0 | 0 | - | +++ | +++ |

| 1.4852 | 1.4852 | GX40NiCrSiNb35-26 | 0,4 | 2,0 | 26 | 35 | Nb | 1100 | 0 | 0 | - | +++ | +++ |

| 1.4855 | 1.4855 | GX40CrNiSiNb24-24 | 0,4 | 2,0 | 24 | 24 | Nb | 1050 | 0 | 0 | - | +++ | ++ |

| 1.4857 | 1.4857 | GX40NiCrSi35-26 | 0,4 | 2,2 | 25 | 35 | 1100 | 0 | 0 | - | +++ | +++ | |

| 1.4859 | 1.4859 | GX10NiCrSiNb32-20 | 0,1 | 1,2 | 20 | 32 | Nb | 1050 | 0 | 0 | - | +++ | +++ |

| 1.4865 | 1.4865 | GX40NiCrSi38-19 | 0,4 | 2,0 | 19 | 38 | 1020 | 0 | 0 | - | +++ | +++ | |

| 1.4869 | 1.4869 | GX50NiCrCoW35-25-15-5 | 0,5 | 1,8 | 25 | 35 | Co, W | 1200 | 0 | 0 | + | +++ | +++ |

| 1.4874 | 1.4874 | GX50NiCrCo20-20-20 | 0,5 | 0,8 | 20 | 20 | Co, W, Nb | 1150 | 0 | 0 | + | +++ | +++ |

| 1.4889 | 1.4889 | GX40NiCrNb45-35 | 0,4 | 1,5* | 35* | 45 | Nb | 1160 | 0 | (+) | - | +++ | +++ |

| 2.4680 | 2.4680 | G-NiCr50Nb | 0,1 | 0,8 | 50 | 50 | Nb | 1050** | 0 | 0 | + | ++ | ++++ |

| 2.4778 | 2.4778 | G-CoCr28 | 0,12 | 1,0 | 28 | 50 | Co | 1200*** | 0 | 0 | ++ | +++ | ++ |

| 2.4815 | 2.4815 | G-NiCr15 | 0,4 | 1,8 | 15 | 60 | 1100 | 0 | 0 | + | +++ | +++ | |

| - | 2.4851 | G-NiCr23Fe | 0,08 | 0,5 | 23 | 60 | Al, Ti | 1200 | 0 | 0 | + | +++ | +++ |

| 2.4879 | 2.4879 | G-NiCr28W | 0,4 | 1,8 | 28 | 48 | W | 1150 | 0 | 0 | - | +++ | ++++ |

| - | 3.4848 | GX15CrNiSi25-20 | 0,15 | 2,0 | 25 | 20 | 1100 | 0 | + | - | +++ | ++ | |

| - | 4.4848 | GX40CrNiSiNb25-20 | 0,4 | 2,0 | 25 | 20 | Nb | 1100 | 0 | + | - | +++ | ++ |

| - | 4.4879 | G-NiCr28W | 0,25 | 1,8 | 28 | 48 | W | 1150 | 0 | 0 | - | +++ | ++++ |

| - | 4.4952 | G-NiCr22Al | 0,2 | 0,7 | 22 | 75 | Al, Ti, Zr | 1150 | 0 | 0 | - | +++ | ++++ |

| - | 5.4848 | GX20CrNiSiNb25-20 | 0,2 | 2,0 | 25 | 20 | Nb | 1100 | 0 | + | - | +++ | ++ |

| - | 5.4849 | GX15NiCrSiNb38-19 | 0,15 | 2,0 | 19 | 38 | Nb | 1020 | 0 | 0 | - | +++ | +++ |

| - | 5.4865 | GX20NiCrSi38-19 | 0,2 | 2,0 | 19 | 38 | 1020 | 0 | 0 | - | +++ | +++ | |

| - | 6.4849 | GX25NiCrSiNb38-19 | 0,25 | 2,0 | 19 | 38 | Nb | 1020 | 0 | 0 | - | +++ | +++ |

| * bei Betriebstemperatur < 1000°C mit abgesenktem Cr- und Si-Gehalt / at operating temperature < 1000°C with lowered Cr- and Si-concentration | a) sulphurous (reductive) | ||||||||||||

| ** bei Ölascheangriff max. 950°C / at oil ash attack max. 950°C | b) nitrogenous / oxygen low | ||||||||||||

| *** für zyklische Erwärmung max. 1100°C / for cyclical heating max. 1100°C | c) carburize | ||||||||||||

| 0 = keine Versprödung / no embrittlement | + = Versprödung / embrittlement | ++ = Versprödung in kurzer Zeit / embrittlement after short time | |||||||||||

| ++++ =sehr hoch / very high | +++ = hoch / high | ++ = mittel / medium | + = gering / low | - = sehr gering / very low | |||||||||

Lohmann Werkstoff‑Nr. Lohmann Material No. | mechanische und physikalische Eigenschaften / mechanical and physical properties | Verwendungshinweise Application note for further use | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mittlere Spannung O1% in MPa für 1% Dehnung nach 10000 h bei °C medium tension O1% in MPa for 1 % expansion after 10000 h at °C | Wärmeausdehnung 10-6 · K-1 zwischen 20°C und °C Thermal expansion 10-6 · K-1 between 20 °C and °C | spezifische Wärme J / (kg · K) bei °C specific heat J / (kg · K) at °C | Wärmeleitfähigkeit W/(m·K) bei °C Thermal conductivity W/(m·K) at °C | ||||||||||||

| 600 | 700 | 800 | 900 | 1000 | 1100 | 400 | 800 | 1000 | 20 | 20 | 100 | 800 | 1000 | ||

| 1.4710 | 19 | 8 | 2,5 | 12,5 | 13,5 | 460 | 24 | für geringe mechanische Beanspruchung,

Beständigkeit gegenüber schwefeligen Gasen / for low mechanical strain, durability against sulphuric gases | |||||||

| 1.4729 | 22 | 9 | 3,5 | 1 | 12,5 | 13,5 | 460 | 24 | 24,8 | 30 | |||||

| 1.4740 | 22 | 9 | 3,5 | 1 | 12,5 | 13,5 | 460 | 20 | |||||||

| 1.4743 | 25 | 10 | 4 | 1,5 | 12,5 | 13,5 | 500 | 18,8 | |||||||

| 1.4745 | 22 | 9 | 3,5 | 1 | 12,5 | 14 | 16 | 500 | 18,8 | ||||||

| 1.4776 | 26 | 11 | 5 | 1,5 | 11,5 | 14 | 16 | 500 | 18,8 | 21 | |||||

| 1.4777 | 26 | 11 | 5 | 1,5 | 11,5 | 14 | 16 | 500 | 18,8 | ||||||

| 1.4823 | 28 | 15 | 8 | 4 | 1 | 13 | 14,5 | 16,6 | 500 | 16,7 | 21 | 35 | 39,6 | für mittlere mech. Beanspruchung bei mgl. Dauertemp. > 900°C/ 1) | |

| 1.4825 | 78 | 44 | 22 | 9 | 17,4 | 18,3 | 18,8 | 500 | 14,8 | 15,5 | 26 | 30 | für hohe mech. Beanspruchung und hoher Zähigkeit

bei Temperaturen > 950°C, gute Temperaturwechselbeständigkeit / for high mechanical strain and high viscosity at stable temperature above 950°C, good resistance to thermal shocks | ||

| 1.4826 | 82 | 46 | 23 | 10 | 17,2 | 18,3 | 18,8 | 500 | 14 | 15 | 25,4 | 28,8 | |||

| 1.4832 | 82 | 46 | 23 | 10 | 17,2 | 18,3 | 19,3 | 500 | 14 | 15 | 25,4 | 28,8 | |||

| 1.4837 | 50 | 26 | 13 | 6 | 17,5 | 18,4 | 19,3 | 500 | 14 | 15 | 25,4 | 28,8 | für hohe mech. Beanspruchung bei möglichst Dauerbeanspruchung > 900°C / for high mechanical strain at stable temperature above 900°C | ||

| 1.4840 | 45 | 21 | 10 | 5 | 16,5 | 17,9 | 18,5 | 500 | |||||||

| 1.4848 | 65 | 36 | 17 | 7 | 2,5 | 17 | 18 | 19 | 500 | 14,6 | 16,7 | 25 | 28 | ||

| 1.4805 | 80 | 45 | 22 | 7,5 | 16,4 | 17,5 | 18,2 | 500 | 14 | 23,8 | 27,7 | für sehr hohe mech. Belastbarkeit und für hohe

Zähigkeitsanforderungen bei Temperaturwechselbelastung bis ca. 1100°C for very high mechanical strain and with high requirements on the viscosity at alternating thermal stress load up to approx. 1100°C | |||

| 1.4806 | 80 | 30 | 17 | 6 | 3 | 15,3 | 17 | 17,6 | 500 | 12 | 12,3 | 23 | 26,8 | ||

| 1.4807 | 15,3 | 17 | 17,6 | 500 | 12 | 12,3 | 23 | 26,8 | |||||||

| 1.4849 | 60 | 38 | 20 | 8 | 15,3 | 17 | 17,6 | 500 | 12 | 12,3 | 23,3 | 26,5 | |||

| 1.4852 | 72 | 41 | 22 | 9 | 3 | 16 | 17,8 | 18,6 | 500 | 12,8 | 13 | 23,5 | 27,7 | ||

| 1.4855 | 80 | 46 | 22 | 7,5 | 16,8 | 18 | 18,5 | 500 | 14 | 15,5 | 24,5 | 27,7 | |||

| 1.4857 | 70 | 40 | 20 | 8 | 15,7 | 17,4 | 18,3 | 500 | 12,8 | 13 | 23,8 | 27,7 | |||

| 1.4859 | 64 | 36 | 15,5 | 5 | 17,6 | 18,7 | 19,5 | 500 | 12,8 | 13 | 23,8 | 27,7 | |||

| 1.4865 | 55 | 32 | 18 | 7 | 3 | 15,3 | 17 | 17,6 | 500 | 12 | 12,2 | 23,3 | 26,5 | ||

| 1.4869 | 17 | 6 | 17,3 | 500 | 10 | 12,6 | 28 | ||||||||

| 1.4874 | 27 | 17 | 15,2 | 16,5 | 17 | 460 | 13,8 | 25 | |||||||

| 1.4889 | 8 | 14,3 | 15,3 | 15,7 | 500 | 11,3 | 30,6 | 36,1 | |||||||

| 2.4680 | 71 | 38 | 18 | 6,8 | 13 | 15 | 15 | 450 | 14,2 | für höchste Temperaturbelastung bis ca. 1200°C, hervorragende Temperaturwechsel- und Zunderbeständigkeit in oxidierender Atmosphäre / for highest thermal stress up to approx. 1200°C, excellence resistance to thermal fatigue stress and resistance to scaling in oxidising atmosphere | |||||

| 2.4778 | 70 | 34 | 16 | 9,5 | 4 | 15 | 16 | 17 | 500 | 8,5 | 21 | ||||

| 2.4815 | 13,3 | 15,3 | 16,5 | 460 | 12,5 | 24 | 27,5 | ||||||||

| 2.4851 | 14,8 | 16,7 | 17,7 | 450 | 11,3 | ||||||||||

| 2.4879 | 70 | 41 | 22 | 10 | 4 | 14,4 | 15,7 | 16,3 | 500 | 11 | 11,3 | 30,6 | 36,1 | ||

| 3.4848 | 63 | 34 | 16 | 6 | 2 | 17 | 18 | 19 | 500 | 14,6 | 16,7 | 25 | 28 | für höhere Zähigkeit vs. 1.4848 / for higher

viscosity vs. 1.4848 für höhere Temperaturwechselfestigkeit vs. 1.4848 / for higher thermal shock resistance vs. 1.4848 wie 2.4879, jedoch mehr Zähigkeit / like 2.4879, but with more viscosity | |

| 4.4848 | 66 | 37 | 18 | 8 | 2,5 | 17 | 18 | 19 | 500 | 14,6 | 16,7 | 23,8 | 11,3 | ||

| 4.4879 | 70 | 41 | 22 | 10 | 4 | 14,4 | 15,7 | 16,3 | 500 | 11 | 11,3 | 30,6 | 36,1 | ||

| 4.4952 | für höchste Temperaturbelast. u. hoher Aufkohlungsbeständigkeit / 2) | ||||||||||||||

| 5.4848 | 63 | 34 | 16 | 6 | 2 | 17 | 18 | 19 | 500 | 14,6 | 16,7 | 25 | 28 | wie entsprechende Normwerkstoffe, jedoch mit

verbesserterTemperaturwechselbeständigkeit und Zähigkeit / like the corresponding standard material, but with revised resistance to thermal fatigue stress and viscosity | |

| 5.4849 | 60 | 38 | 20 | 8 | 15,3 | 17 | 17,6 | 500 | 12 | 12,3 | 23,3 | 26,5 | |||

| 5.4865 | 55 | 32 | 18 | 7 | 3 | 15,3 | 17 | 17,6 | 500 | 12 | 12,2 | 23,3 | 26,5 | ||

| 6.4849 | 60 | 38 | 20 | 8 | 15,3 | 17 | 17,6 | 500 | 12 | 12,3 | 23,3 | 26,5 | |||

| 1) for medium mechanical strain at stable temperature above 900°C | |||||||||||||||

| 2) for highest thermal stress and high resistance against carbonisation | |||||||||||||||