- Company

- Products

- Careers

- Environment

- News

- Downloads

- Contact

Renewable Energy

From photovoltaic systems and hydropower to the steel recycling system

A photovoltaic system was installed on the roofs of the production halls of the Friedr. Lohmann GmbH and put into operation in late 2010. The system consisting of 3142 thin-film solar modules with a total output of 243.51 kilowatts peak was mounted on three large, flat roofs with a total area of 3000 m². The forecast annual output of 200,000 kilowatt hours is enough to supply a neighborhood with 50 four-person households with power for one year. This saves 180 tons of CO² per year. After starting to generate electricity using hydropower and recovering heat to heat water, Lohmann began using the next environmentally friendly power source, the new photovoltaic system, in 2011.

It could also be described as follows: Environmental protection and saving resources are playing an increasingly important role at the Friedr. Lohmann GmbH in our production processes and in determining how we make investments. Parallel to the steel industry rich in tradition in the Ruhr valley, it is also becoming a small, integrated power generation region through the use of hydropower, solar power, and heat recovery systems. This in turn means the steel from Lohmann is becoming “greener and greener”.

Hydropower was already in use in the pre-Christian era. In 100 B.C., the Roman architect Vitruvius described a grain mill that was driven by an undershot water wheel that, in principle, differs little from modern water mills. The generation of power in small hydroelectric power plants marks the beginning of public electrical supply systems. As technology advanced, the use of hydroelectric power expanded on large rivers since the beginning of the 20th century and enabled electricity to be generated more economically.

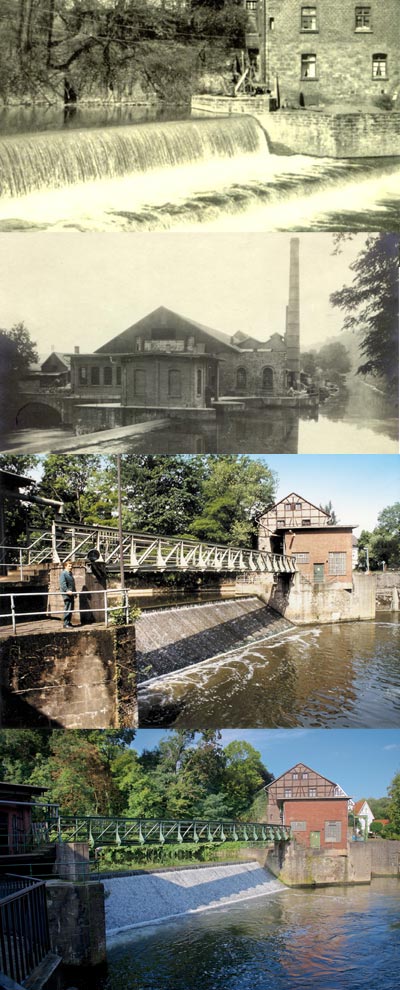

Against the background of the general discussion of the environment, people today are taking a new look at the numerous small hydroelectric power plants that were shut down in recent decades. Lohmann has been granted water use rights in Witten-Herbede. The grain mill, the rights for which reach back to the Middle Ages, is mentioned in 1770 as being owned by the former Baroness von Elverfeldt. Ownership was transferred to Lohmann in the middle of the 19th century when they purchased the mill and the surrounding properties. The Lohmann hydroelectric power plant has evolved from a grain mill driven by a water wheel on the mill channel in Herbede to a modern hydroelectric power plant consisting of four Francis turbines and a fully automatic control system. It includes a headwater channel that is used to supply water to the turbines and a tailwater channel to discharge the water into the Ruhr River. The weir located between the headwater and tailwater channels has a vertical drop of about three meters. The water flow rate of the turbines is 30.5 m³/s. The plant has a power output of about 600 kW. Approximately 4 million kWh are generated annually, which means about 1,200 households can be supplied with power.

The principle of hydropower is to convert mechanical motion or force into electrical energy using gears and generators. The electricity generated by the plant is consumed by our facilities and helps us make our production climate-neutral. Electricity from hydropower means resources like coal, oil, and gas are saved while protecting the climate and the environment at the same time. One kilowatt hour generated by hydropower saves one kilogram of carbon dioxide emissions (CO2 emissions) as well as the emissions of other pollutants. The impact and damage to the environment resulting from the use of fossil fuels and atomic energy are avoided when water is used to generate power.

The supply of resources – which is currently hot topic – is also limited due to increasing consumption. Protecting resources and the climate of the Earth are becoming more and more important in an advanced industrialized world (China, India, Turkey, new EU member countries) that continuously focuses on growth.

Hydroelectric power plants demonstrate that water used in this manner is a gift of nature, and therefore that hydroelectric power is a natural product of the highest quality through which we benefit from nature while protecting nature!

Maintaining a heightened awareness of the environment is part of the moral identity of the Friedr. Lohmann GmbH. In addition to striving to maintain and improve the high quality of our steel products, increasingly higher demands are being placed on the environmental compatibility of the technologies used.

The measures required for certification of an environmental management system according to ISO 14001 were implemented successfully. This certifies that the Friedr. Lohmann GmbH has introduced and maintains an environmental management program to realize its environmental objectives. By converting parts of the production plants from coal and gas furnaces to electric, natural gas, and shielding gas furnaces using advanced burner and control technologies as well as automatic control systems, we are not only able to meet the emission limits required by law, but even stay far below them.

Rainwater is valuable!

Rainwater is fed back into the natural water cycle using corresponding facilities. These facilities prevent rainwater from flowing into the sewer system.

Almost no other material has so much potential to achieve a circular economy. Scrap-based steel production is already an integral part of our production. In Germany, we work with a network of collection, sorting, and processing facilities for the steel scrap we produce. This recycling system operates efficiently, and therefore contributes directly to a significant reduction in CO2 emissions.

In order to further advance sustainability, the circular materials management system at the Friedr. Lohmann GmbH is constantly being optimized. For example, the scrap collected as waste material during production is reused as a feedstock in our steel mill or in our foundry. Products that become waste material at our customers after use are repaired if possible, put back on the market again as a product, and can therefore be used again, for example as a machine part. If the product cannot be repaired, then the unusable products are returned to our steel mill or foundry for use as a feedstock and processed to make new products. This ensures almost 100% of our products are recycled.

We also strive to recycle 100% of the materials that leave our company as waste in the framework of a sustainable waste management system.

Climate and environmental protection have always played an important role at our company.